The orthodox well water system used a bucket to draw water. In modern times, the concept of well systems is based on the latest machinery, which gives ease of use, safe water, and reasonable water pressure. If you own a well system or you are planning to drill one on your property or thinking to buy a house with a private well, you may be interested in knowing how a water well works.

Let’s get to know your well water system in more detail!

From where a Well Draws Water

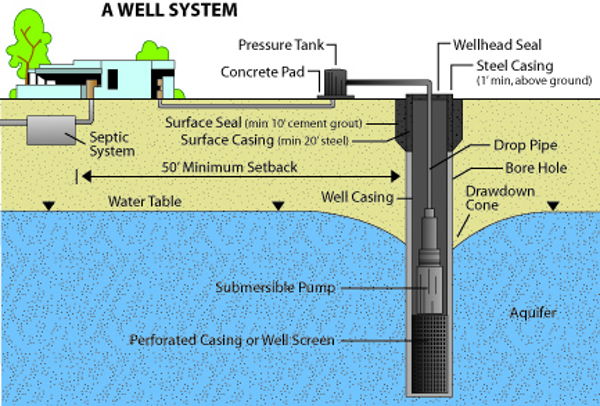

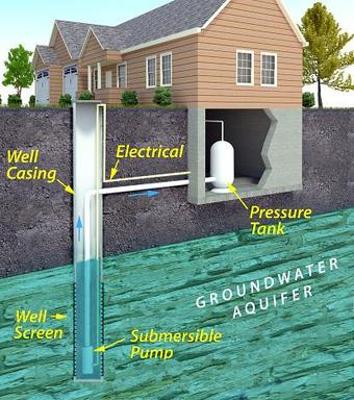

A water well takes water from underground aquifer. Aquifers are layers of soil and rock which contain water in between them. Water can move across the layers in aquifers and from one aquifer to another aquifer. When you are drilling for a well, the basic purpose is to reach the aquifer so the water inside it can be accessed.

Let’s look at the basic components of a well water system and how they work!

A standard well water system consists of the following components.

- The Well Pump (water pump)

- Well Casing

- Control Box & Pressure Switch

- Pressure Tank

- Well Cap

- Well Screen

The Well Pump – It is also known as a water pump, and it is the most important component of a well system. It is responsible for pumping out water from the well. You can either use above ground or submersible water pumps for this purpose. The amount of water needed and the type of well determines which pump is best for you. Submersible pumps are placed deep inside the well, just under the water level.

Well Casing – Well casing is the cemented wall on the sides of the well. It protects your water from getting contaminated from sides and stop soil seepage. A well casing can be made from PVC, carbon steel, and stainless steel. The choice of material depends upon the geologic formation. Drilling companies are experts in this domain and will suggest the best material for well casing.

Pressure Switch and Control Box – Control box controls the settings on your well. A pressure switch is installed to regulate the drilling pressure and supply pressure. Both are critical components of any well system as they regulate the working of the well pump. Well pumps are not meant to work 24/7. They usually operate when the demand for water is high, and the water pressure is dropped below a certain level. Pressure switch ensures that the typical pressure of 40 PSI is maintained, and it controls the working of well pump to keep the water pressure at 40 PSI or the pre-determined settings.

Pressure Tank – Pressure tanks are used to store water and maintain pressure throughout the distribution system. Pressure tanks are available in different sizes and materials. You must select the size which meets your needs. An average American family uses 300 gallons of water per day. Also, see this tutorial to understand ideal water pressure from your well.

Well Cap – Well caps are important when it comes to keeping your well safe from debris, animal waste, insects, and small animals. Well caps come with ventilators to normalize the pressure difference inside and outside of the well.

Well Screen – Well screen is a filtration media attached on the lower side of the well casing to keep sand, gravel, dust, and other sediments away from water. Well screen allows water to enter the bottom of the well. The water is pumped via well pump to your home. If these substances are allowed to flow in the water, it can cause problems for the water pump.

Common Issues with Well Water

Most private wells produce hard water. Hard water is rich in calcium and magnesium. These minerals are good for your health but can damage your home’s water pipes, fixtures, and appliances. The white scale you see on your faucets is actually hard water residue.

Sometimes well water isn’t suitable for bathing. Moreover, it can also cause hair loss, itching, or discolor your hair. You can fix these problems by identifying the cause and installing the right filter.

When water moves underground, it dissolves different contaminants. The major ones are solids like iron, calcium, magnesium, and other metals. Another common issue is sediment. Some wells may also have sulfur gas, arsenic, nitrates, and radioactive materials. It depends on where your well is located and the overall water quality in the area.

Hence, testing your well water annually and upgrading/modifying your home’s water treatment system is important.

Types of Water Wells

Bored or Dug Wells

Bored or dug wells were traditionally constructed using hand shovels or picks. The hole (well) was then lined with stones, bricks, or cement for support and to prevent the well from collapsing. The well was covered with a wood, stone, or concrete cap.

Modern dug wells are constructed using power equipment and are 10-30 feet deep. They are usually constructed in areas with underground water near the earth’s surface. These wells are least preferred because they are at a greater risk of contamination and flooding.

Drilled Wells

Drilled wells are the most common wells in the USA. They are drilled using heavyweight machinery and can have a depth of 10-60 feet or up to 1000 feet.

Industrial wells or wells supplying large population groups can be as deep as 3000 feet.

These wells are typically constructed by licensed professionals using heavyweight rotary drills and auger bits. Drilled wells usually last up to 50-60 years with fair usage and produce better quality water than bored wells.

Driven Wells

Driven wells are dug in areas with loose soils, such as sand or gravel. They are dug using a small-diameter pipe with a screen attached at its bottom. The pipe taps the stone containing water, and then water is drawn with the help of a well pump.

FAQ

Do I need a water filter for well water?

It depends on the quality of water your well produces. Some wells only need a sediment filter and a water softener. Conversely, some wells need a whole house water system along with a drinking water filter to make well water consumable. Make sure you get your well water tested before installing a water filter.

Who regulates well water quality and well water construction?

The well owner is responsible for maintaining the well and water quality. However, well construction, repair & maintenance, or sealing must be carried out by a certified well contractor as per the local laws.

EPA recommends annual testing for well water or whenever you notice a visible change in water quality. It has given directions on how to deal with common well water contaminants.

Can I dig my own well?

No. You cannot dig your own well in most states. A few states allow property owners to dig shallow wells at their property, but only after obtaining permits.

It is required by law to hire a certified contractor for drilling, modifying, or sealing a water well.

What to do if the underground water level decreases?

If the underground water level decreases in your well, you have two options. You can increase the depth of your well to tap more water underneath. The other option is to dig a new well. It is costly and must only be adopted when you don’t have any other solution. If you are going for a new well, make sure you seal the old one.

What to do if the water pressure decreases?

Well water pressure can decrease due to several reasons. It can happen due to a faulty water pump, clogged well screen, decreased water level, and sediment deposit in your plumbing system. To deal with the low water pressure problem, you need to identify the cause first. Once you have pinpointed the issue, relevant measures can be taken.

What to do if the well casing is damaged?

If your well’s casing is damaged, you must call your well contractor and have him look at it. It must be repaired ASAP to avoid bugs and contaminants entering your water.

What to do if the well screen is clogged?

Clogged well screen can be cleaned with the help of cleaning agents/granular acids. You can read more about it here.

Water runs out too often; what can I do to avoid it?

If you face dry taps with your well often, you can deal with this problem by installing a larger water tank. You may also need to install a more powerful pump or install constant pressure switches. These fixes will only work if your well produces enough water to meet your home’s needs.

Is well water costly than city water?

You don’t have to pay to use well water, unlike city water. However, the well owner is responsible for drilling a well, installing filters, testing water, and maintaining water quality. The initial costs are usually high, but well water is cheaper in the long run.

Is well water the same as spring water?

No. Well water is not the same as spring water. Well water is pumped from an aquifer; spring water is found where the aquifer is close to the earth’s surface.